Globax portfolio

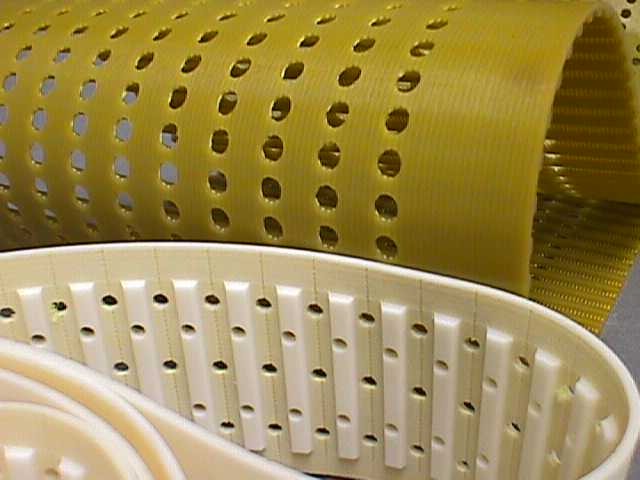

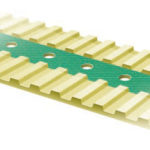

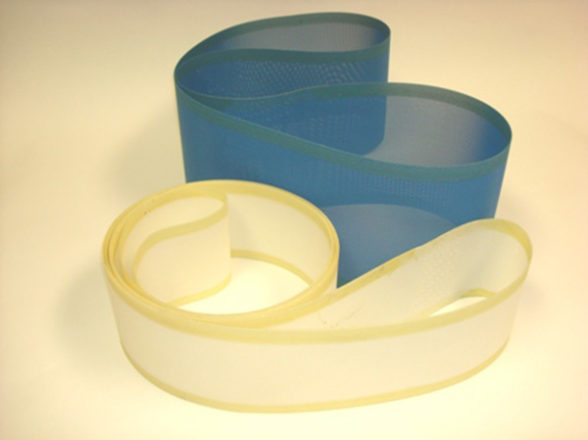

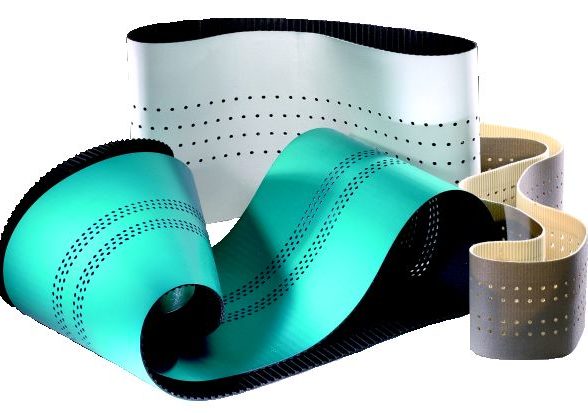

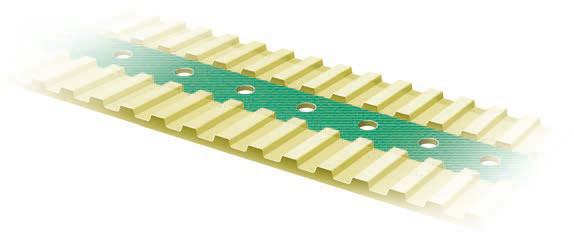

Vacuum / Perforated Belts

Details

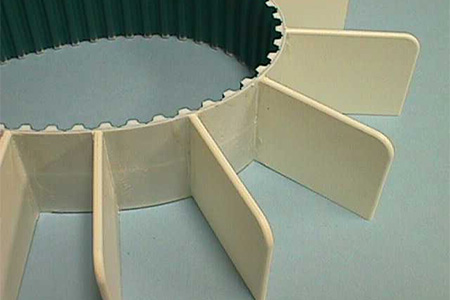

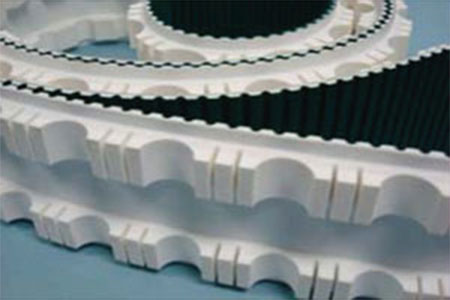

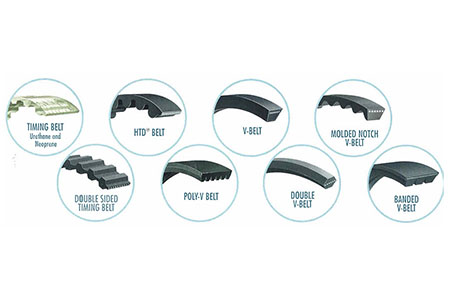

- Category: SPLTY BELTING & FAB, Timing Belts, Timing Vacuum Belts or Perforated Belts

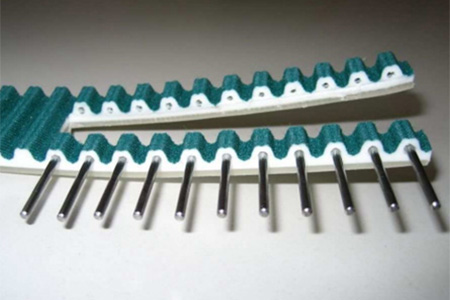

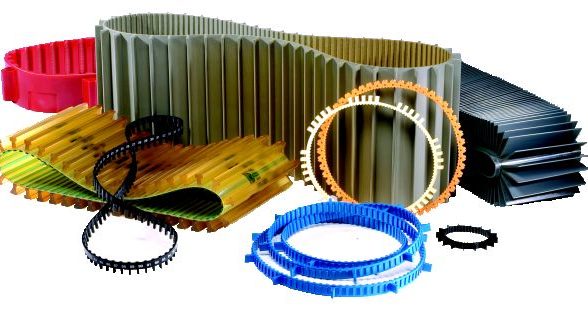

- Holes for Vacuum or Attachments

- Various Sizes, Shapes and Patterns

- For Timing or Conveyor Belts

Description

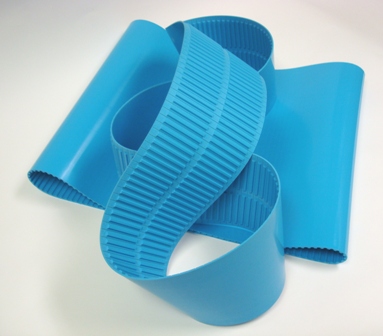

Vacuum Belts provide positive holding power for very light weight products, such as paper, plastic film and fabrics. Hole size and pattern can be modified to meet the applications you need.

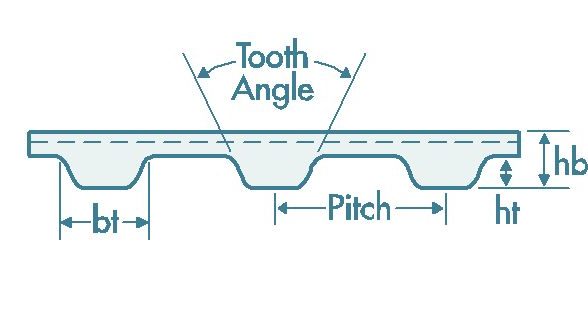

| Vacuum Sizes and Shapes | StaggeredPattern |  |

| SquarePattern |  |

|

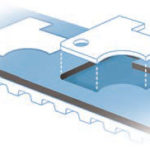

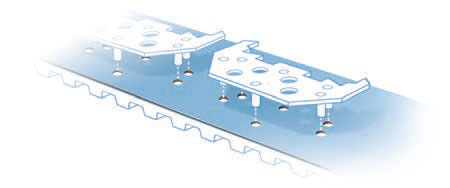

| PerforatedBeltforPositioning |  |

|

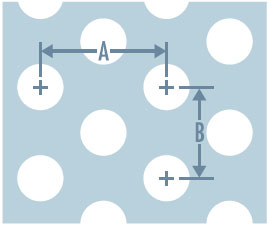

| HoleDimensioning Centerto Center |  |

|

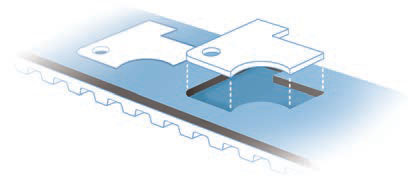

| BeltwithMachinedCavity |  |

|

| Any Hole Shape Available (Standard & Custom) |  |

|

| ToothRemoval |  |

| Hole Patterns & Shapes |

Hole size and pattern (percentage of open air) can be modified to meet the application’s need. There are endless possibilities. There are some standard patterns available, but usually each unique application requires its unique hole pattern. A simple drawing with dimensioning is all that is required to have a die made for perforating. Please contact our Technical Department. Note: For vacuum applications, it is possible under certain circumstances, to extrude urethane timing belts with cord spacing that allows for placing the holes between cords so that the cords are not cut during perforation. |

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.