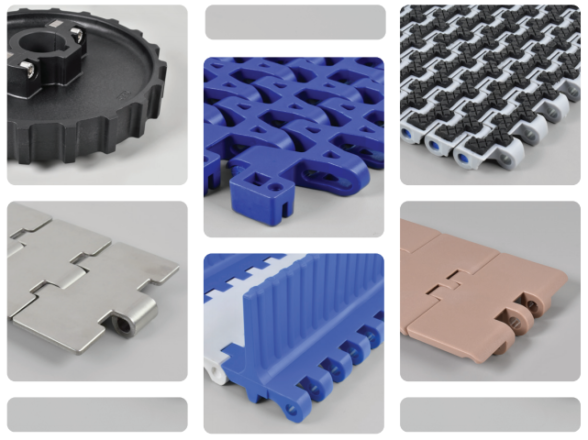

Globax portfolio

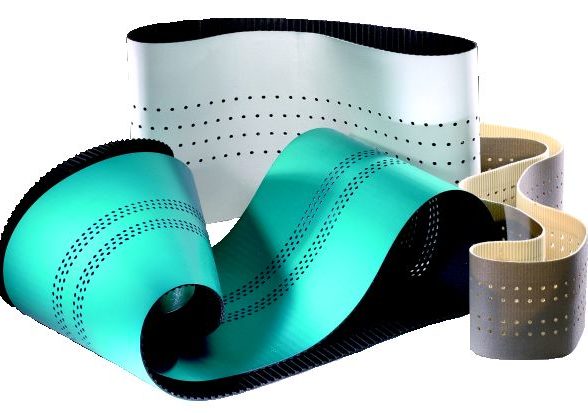

Custom Belt Machining

Details

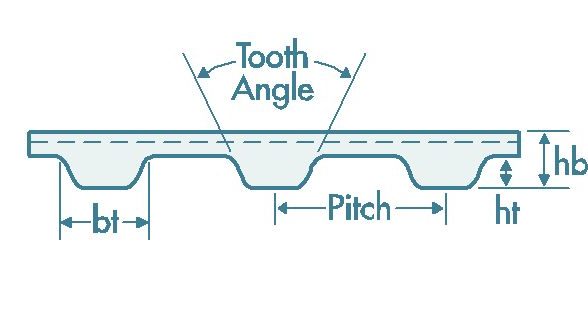

- Category: SPLTY BELTING & FAB, Timing Belts

- Manufactured belts to your specifications

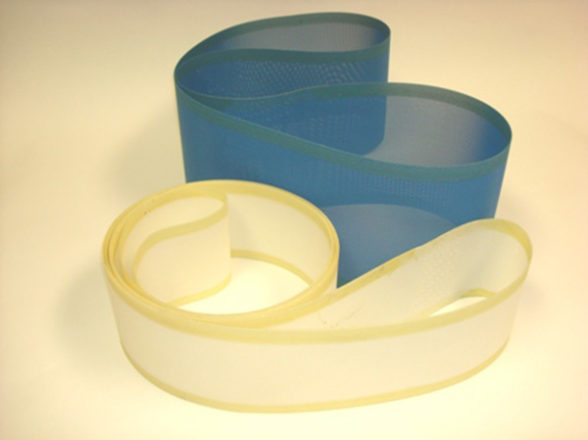

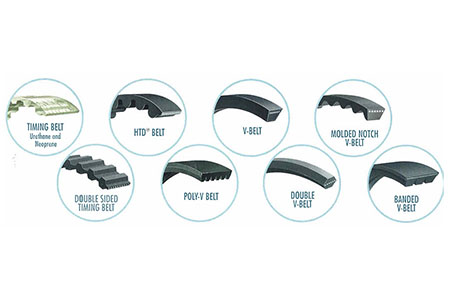

- Choose from a wide variety of belts

- Large selection of belt surface coverings

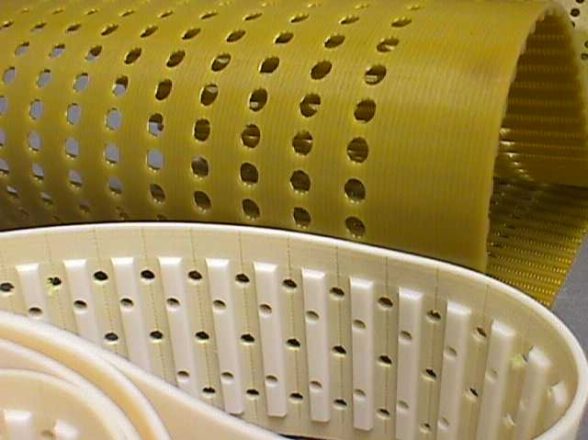

- Hole perforating and belt detailing to your specs

Description

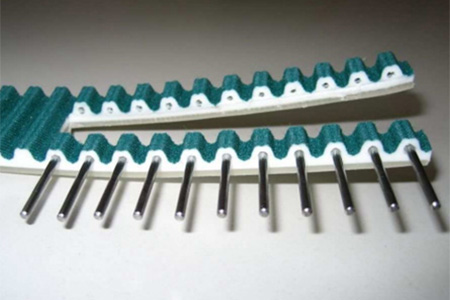

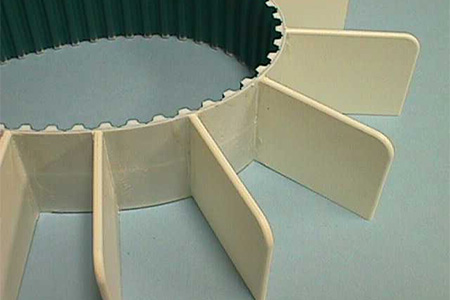

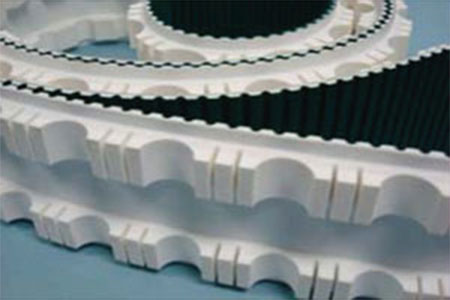

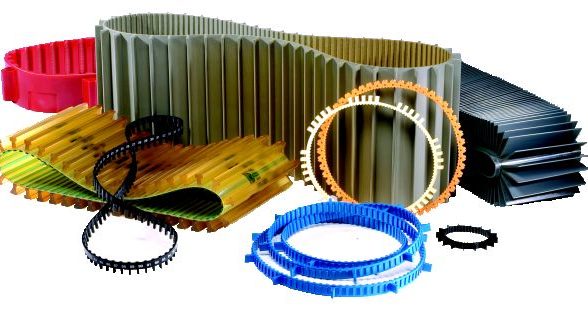

F.N. Sheppard & Co. provides custom belt fabricating services for customers in diverse industries. We offer 14 different processes, for projects as small as a prototype to large production volumes. To maximize grip and control and minimize the crushing of your product, we feature precision contouring of radius, rectangular, square, V-shape, and custom shapes. Additionally, we provide extrusion services for materials and covers up to 6.5 inches in width and 40-90 durometers in hardness, with virtually limitless thickness. We have slit, vacuum, and knife cutting expertise for materials up to 8 feet wide and .75 inches thick, with minimal hole features of 1 mm. With the ability to grind any flat, conveyer, timing, Poly-V, HTD®, and V-belt surface- side, top and/or bottom- to precise tolerances, we can also create new surfaces, edges, grooves, teeth, contours or slots. We present 9 different methods of splicing and 6 different methods of bonding.

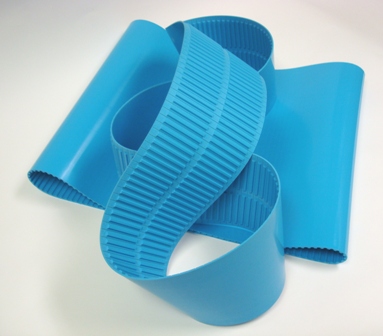

Featuring a variety of materials, we ensure that our capabilities meet your needs. Our seamless belts are truly endless, greatly increasing reliability, durability and longevity, and resulting in a reduction in breakdowns and consequent down time.

F.N. Sheppard & Co. is your custom belt fabricating expert. Contact us or see below for more information on how we can provide all of your belt services with satisfaction guaranteed.

- Profiling – Precision contours: radius, rectangular, square, V-shape or any custom.

- Grinding – Machining any belt surface-side, top and/ or bottom to precise tolerances.

- Serrating – Typically done to provide more flexibility when using a thicker covering.

- Tooth Removal – Timing Teeth can be removed in any configuration or grouping

| General Capabilities |

|

| Fabrication Process |

|

| Fabricated Shapes |

|

| Materials |

|

| Extrude |

|

| Extruding Width | Up to 6.5 in |

| Extrusion Hardness | 40 to 90 Durometer |

| Cutting |

|

| Cutting Width | Up to 8 ft |

| Cutting Thickness | Up to 0.75 in |

| Minimum Hole Feature | 1 mm |

| Clicker Press (Hole Pattern) Width | Up to 2 m |

| Grinding |

|

| Endless Belts |

|

| Splices |

|

| Mechanical Laced |

|

| Bonding |

|

| Welding Features |

|

| Coatings |

|

| Coating Process |

|

| Molded Urethane Parts |

|

| Additional Services |

|

| Production Volume | Prototype to Large Scale Production Volume Run |

| Lead Time |

|

Additional Information

| Industry Focus |

|

| Industry Standards |

|

| File Formats |

|

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.