Details

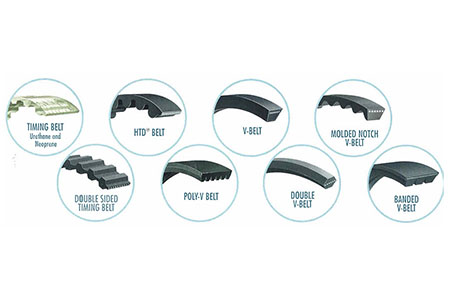

- Category: Anaconda Belts, Timing Belts

- Quiet

- Fast

- Precise

- Tough

Description

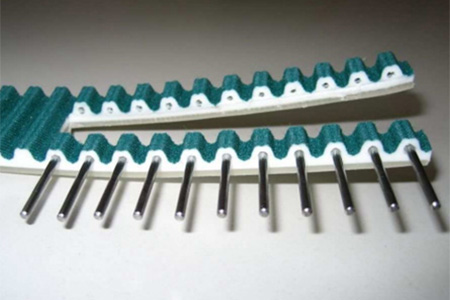

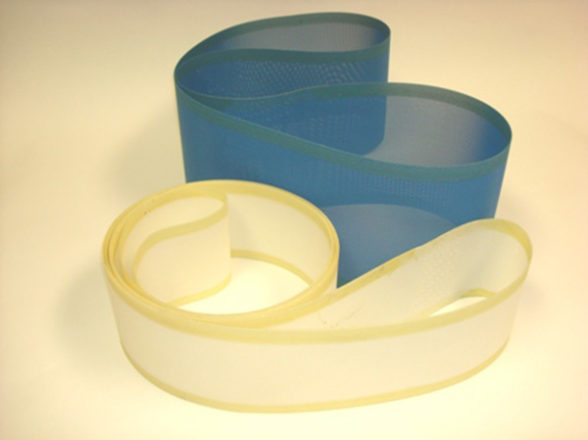

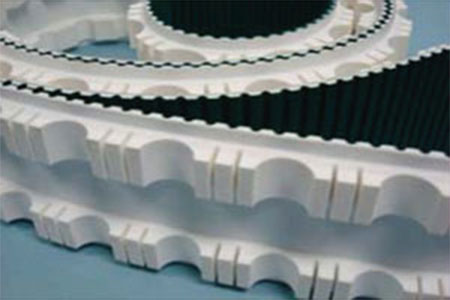

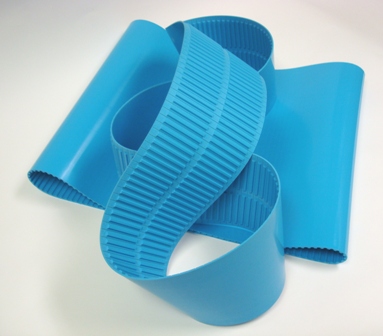

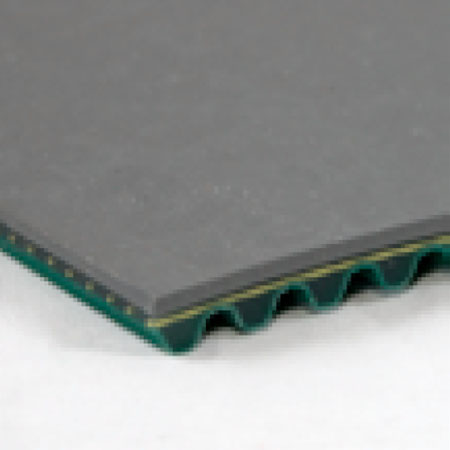

Anaconda is a patented new product created by F.N. Sheppard® for high-speed conveying applications where precision tracking is essential. Anaconda is both a synchronous belt and a conveyor belt in one!

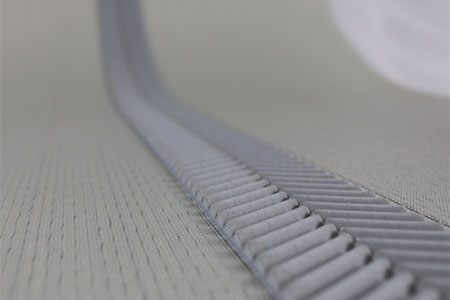

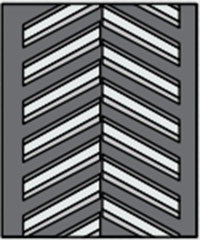

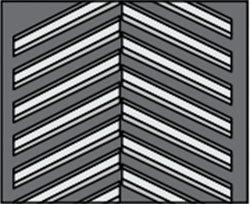

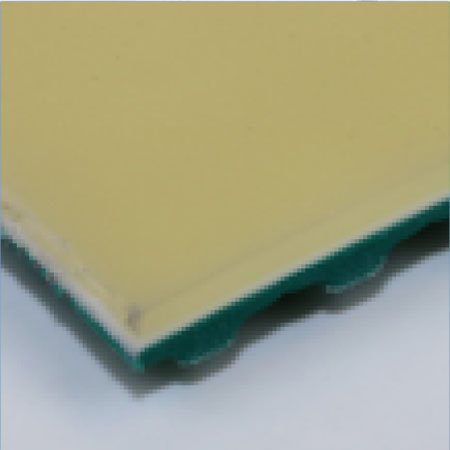

The unibody construction consists of an extruded urethane flat section and a offset helical drive section both reinforced with high strength Kevlar™ reinforcement. This homogeneous design not only provides precise low-noise indexing and accurate belt tracking, it also offers low-friction high-strength “wings” on either side of the drive teeth that glide smooth across your conveyor path using low energy.

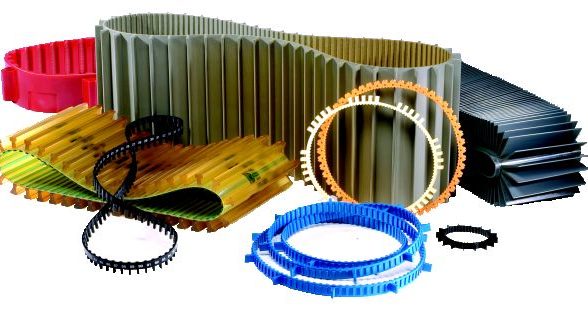

32mm |

Comparison of the 32mm and 52mm |

50mm |

WIDTH OPTIONS |

TRACK WIDTH (mm) MAX BELT WIDTH (mm) | |

| 32 | 210 | |

| 50 | 535 | |

| INDUSTRIES |

|

|

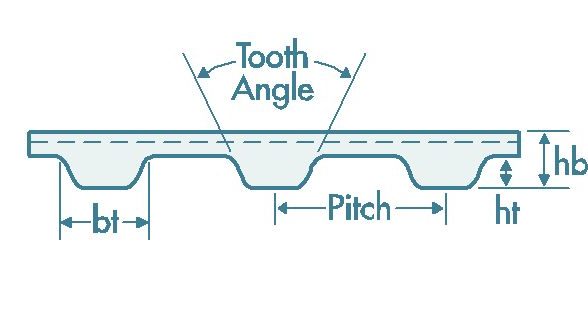

| QUIET RUNNING | 8mm offset helical pitch with gray poymide fabric on tooth side offers wear resistance and low noise. | |

| BENEFITS OF ANACONDA | |

| Quiet Running | Low installed tension |

| True Self Tracking | No Splice on Drive Pulley |

| Precision Indexing | Low Friction on Wings |

|

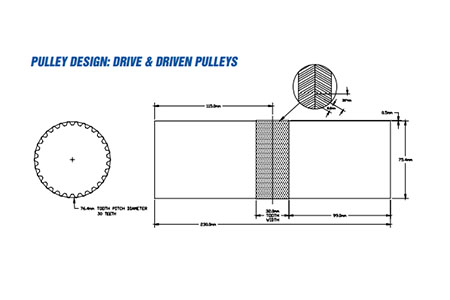

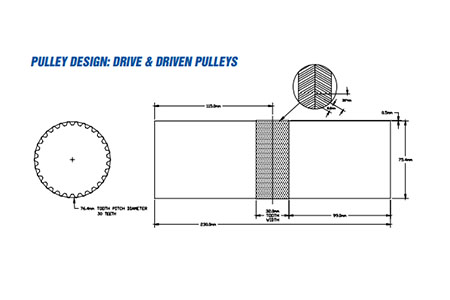

| PULLEY DESIGN: DRIVE & DRIVEN PULLEYS | ||

| SPECIFICATIONS | Belt Body | Thermoplastic Urethane – non FDA |

| Durometer | 85 shore A | |

| Cord Reinforcement | Kevlar™ | |

| Belt Drive Side – helical offset teeth | Gray polyamide fabric | |

| Belt Drive Side – Wings – flat sections | Gray polyester fabric | |

| Minimum Drive Pulley Diameter | 60mm toothed | |

| Minimum Driven Pulley Diameter | 60mm – can be smooth, but deep groove (see sketch) | |

| Max Operation Speed | 2000 fpm | |

| COEFFICIENT OF FRICTION | Anaconda wings against Steel: 0.119 | Anaconda wings against UHMW: 0.130 |

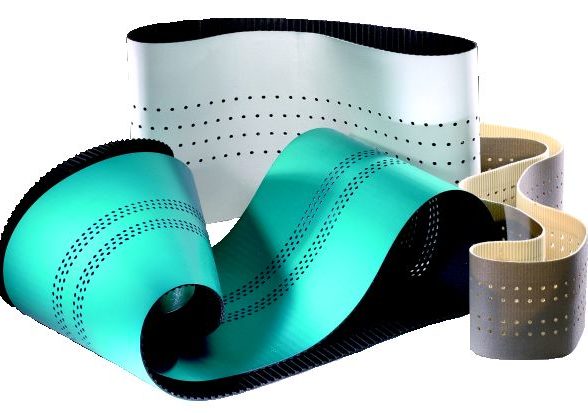

Silicone Non stick low or high COF. |

|

High Grip High COF natural latex |

|

|

Release Release surface with high |

|

Delicate Handling Soft, compressible, flexible |

|

Standard Grip 55Adurometer PVC Blend for |

|

Cushioning Firm, compressible, flexible |

|

Medium Grip 40Adurometer PVC Blend |

|

Custom Materials Many options available for |

|

Low Grip Alow COF coating for |

|

Specialty Sponge Resistance to low & high |

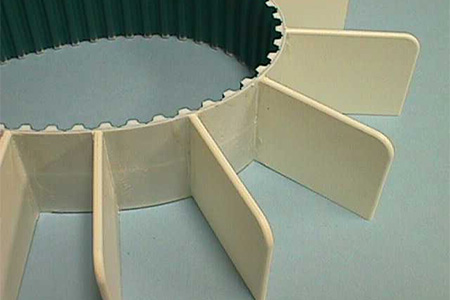

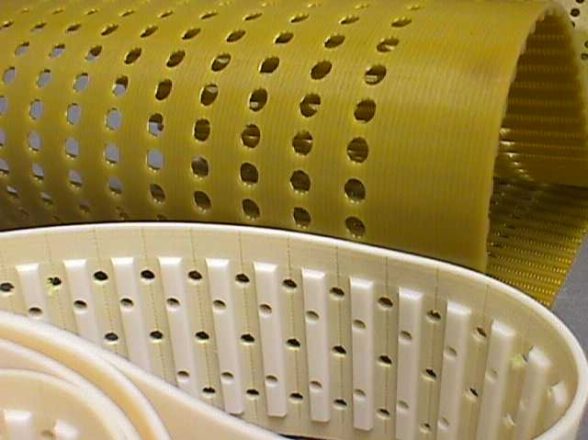

| HOLE SHAPE ACTIONS | |

|

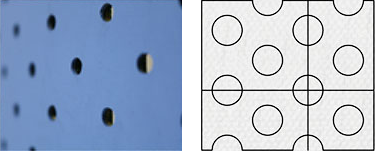

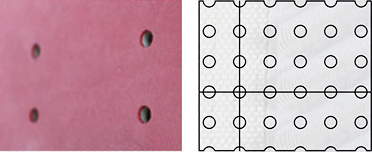

Various vacuum hole patterns provide positive holding power for light products such as paper, plastic film and non-woven fabrics. |

| STAGGERED HOLE | SQUARE HOLE |

|

|

| Hole size and pattern can be modified to meet the application demands. F.N. Sheppard has sophisticated perforating equipment to ensure accuracy and offer various shapes and patterns. | Standard patterns are available and holes can be perforated across entire belt with, including the tooth area. |

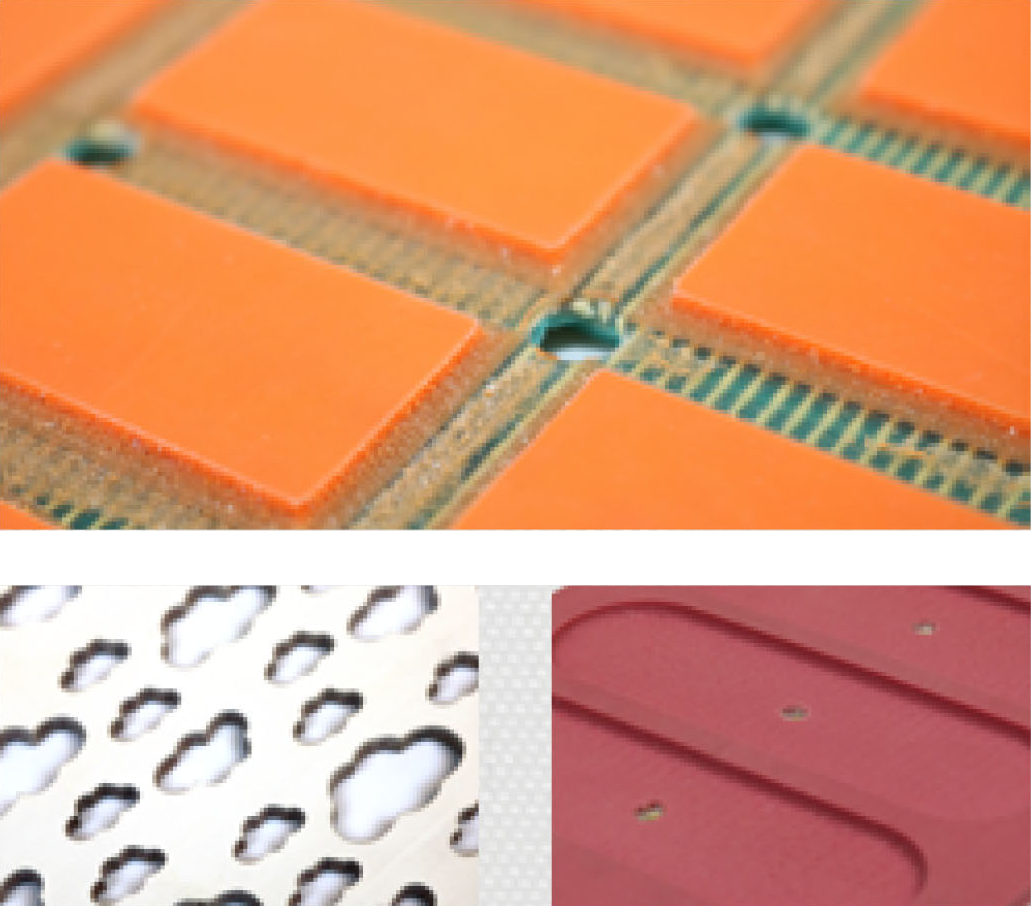

| ADVANCED PROCESS | |

|

Contouring with slots, grooves or pockets can be accommodated. These special designs allow for better vacuum control of the product being conveyed. F.N. Sheppard can machine any belt surface to precise tolerances. We can assist in designing the most effective belt for your application. |

To view or download, click PDF image above

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.