From need to concept, to final design and finished product, F.N. Sheppard & Co. has the ability to produce many different Conveyor Belts you would need to keep your business running smoothly. Not sure what you need or where to start? Ask our engineers and designers who are always here for you.

F.N. Sheppard has the ability to create any Belt Types, styles, and designs for practically any belting application you could need. We offer theses Belting Types and services around the globe.

Time is money and when you need it now, you need it done right the first time. F.N. Sheppard & Co. is an engineering friendly Custom Fabricating belting company. Our designers and engineers work with your engineers and designers so that your belting product is done on time and done right, the first time.

Meeting the toughest international standards for food contact belting materials is one of F.N. Sheppard's top priorities. Using Thermoplastic Elastomer (TPE) materials allows our Food Grade Belts to meet the demands of food hygiene levels that are superior in the food grade belting industry.

F. N. Sheppard & Co. also markets many special high performance flexible composite products. Many are used in packaging, food processing, electronics and chemical processing industries. From PTFE / Silicone coated fiberglass fabrics to PTFE coated Kevlar® fabrics. If we don't have what you need, we will design it, engineer it, and manufacture it.

Offering the highest quality variety of belt types created from different designs that are suitable for vacuum, fluff pulp, dewatering, and solid/liquid separation keeps F.N. Sheppard & Co. a leader in the Screen and Filter Belting industry. You need it, we will make it for you.

F.N. Sheppard & Co. has it when it comes to Woundless Endless Specialty Belts.

Contact us today and let us work with your engineering team to get you project on the move.

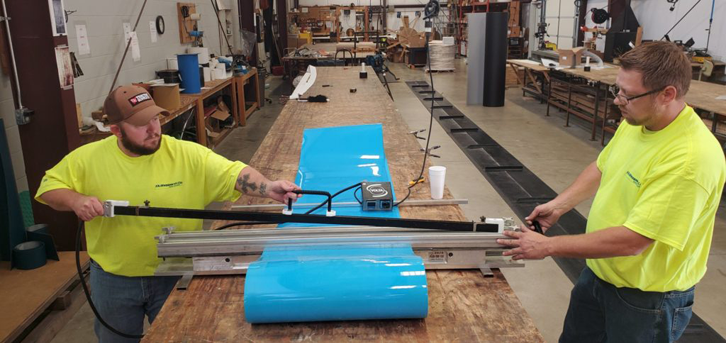

Thermoplastic urethane is very user friendly. It allows for quick splicing with the means of heat welding the belt ends.

Belting from F.N. Sheppard & Co. is available in open-ended rolls (standard rolls 100-500 ft.,) or cut and welded to your exact length required.

F.N. Sheppard & Co. believes that providing on-site service where we can is a very important aspect of our business. Belt installation and belt repair are just a few things that we are able to do. Contact us today about the areas in which we provide on-site services.