Globax portfolio

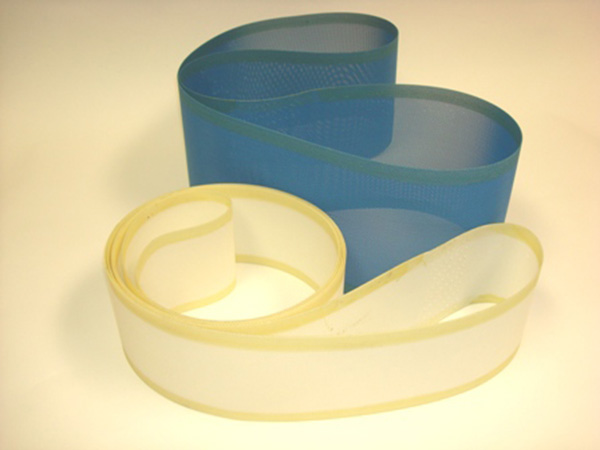

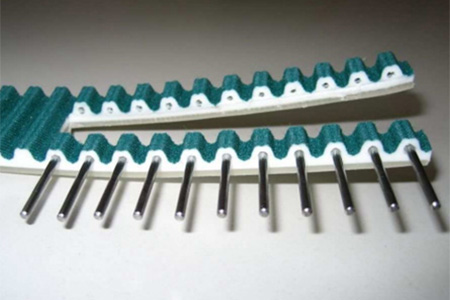

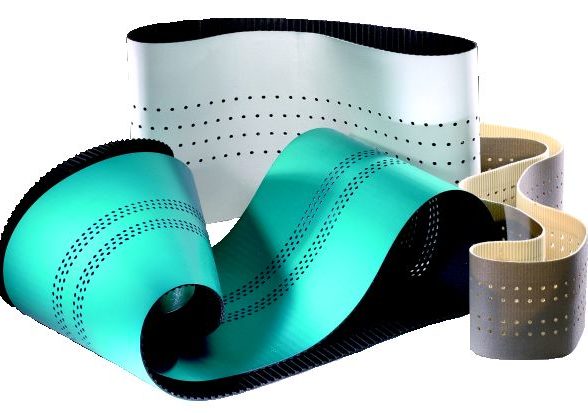

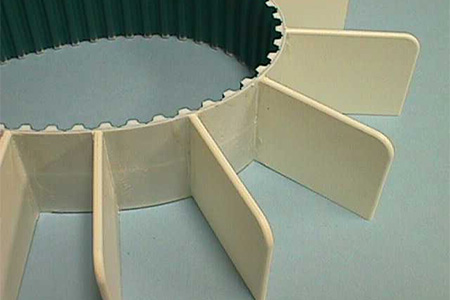

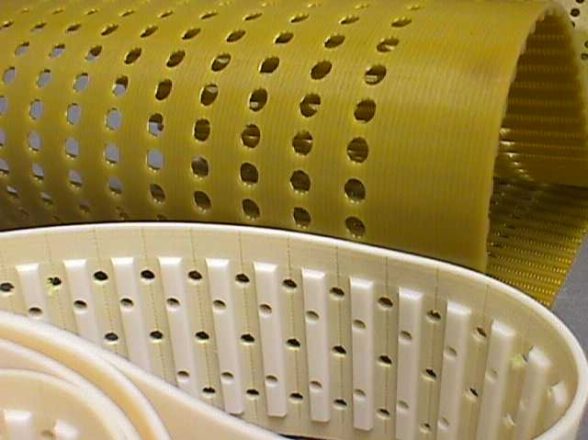

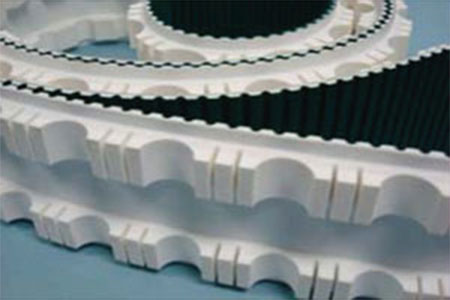

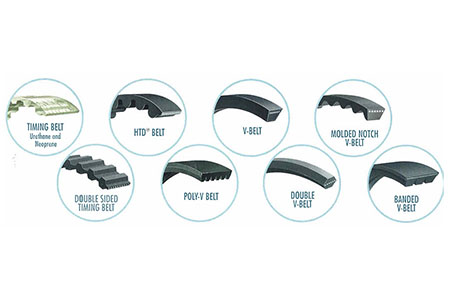

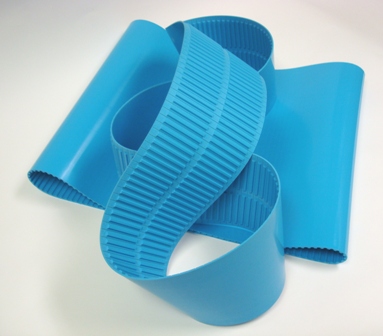

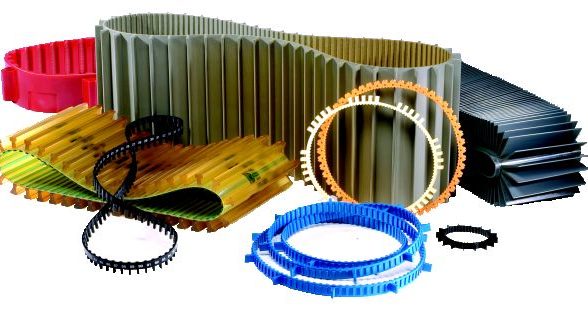

Screen and Filter Belts

Details

- Category: Conveyor Belts, Screen & Filter Belts

- Polyester Linear Screen

- Vacuum Filter, Woven Press, Dryer Fabrics

- Excellent Stability and Good Wear Resistance

- Woven Endless Seams or Metal Clipper Laced

Description

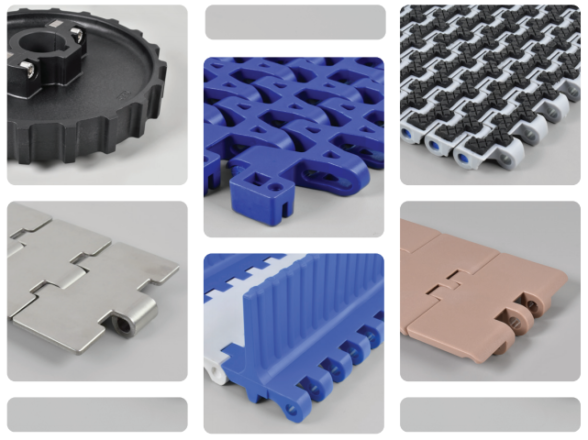

We offer a variety of belt types of different designs that are suitable for vacuum, fluff pulp, dewatering, and solid/liquid separation.

- – Different weave styles for optimal combination of strength, air permeability and cake release

- – Some are co-extruded Poly/PTFE for better release characteristics

- – Coated edges for a long and trouble-free service life

- – Woven endless seams or metal clipper for easy installation of the belt

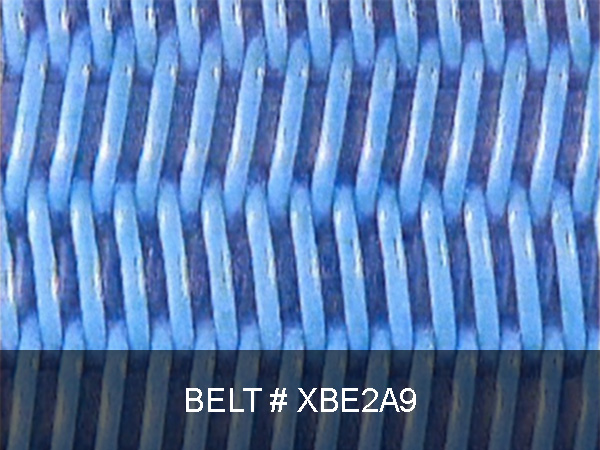

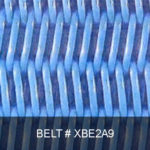

100% Monofilament Spiral Fabric with Improved Hydrolysis Resistance

Products Strengths

- Co-extruded Poly/Teflon Spiral Fabrics

- Improved hydrolysis resistance

- Superior abrasion resistance

- Smooth surface and high contact

- Cleanest running design

- Maximum dimensional stability and strength

- Retains permeability throughout life

Desing Specifications

- Poly/Teflon 7PT CFM: 90

- 16 PLI @ 300° F

- 500 PLI Breaking Strength

- Max Operating Temp. 415° F

- Weight .279 lbs/ft²

- No seam is required, the fabric ends are joined together at

the time of installation

To view or download, click PDF image above

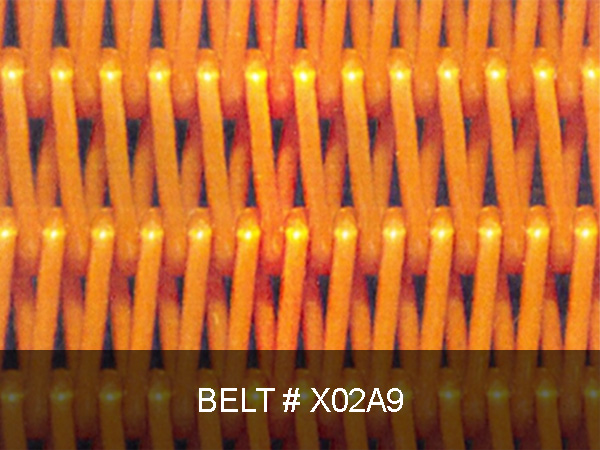

100% Monofilament Spiral Fabric with Improved Contamination Resistance

Products Strengths

- Co-extruded Poly/Teflon Spiral Fabrics

- Improved contamination resistance

- Smooth surface and high contact

- Clean running

- Maximum dimensional stability and strength

- Retains permeability throughout life

Specifications

- Poly/Teflon 105PT

- CFM: 1200

- MD (machine direction) yarn dia. .105 mm

- CD (cross direction) yarn dia. .9 to .105 mm

- Estimated overall thickness (measured) 3.8 mm

- Min. Pulley: 4” Dia.

- Max Operating Temp: 400°F

- Normal Working Tension: 12-18 pli

- Lower Permeability is achieved with monofilament stuffers

- No seam is required, the fabric ends are joined together at the time of installation

To view or download, click PDF image above

100% Monofilament Spiral Fabric with Improved Hydrolysis Resistance

Products Strengths

- Improved hydrolysis resistance

- Superior abrasion resistance

- Smooth surface and high contact

- Cleanest running design

- Maximum dimensional stability and strength

- Retains permeability throughout life

Design Specifications

- Polyester Monofilament 6HT CFM: 900

- 500 PLI Breaking Strength

- Max Operating Temp. 450° F/li>

- Permeability is achieved with solid ribbon stuffers

- Estimated overall thickness (measured) 3.8 mm

- Min. Pulley: 4” Dia.

- Max Operating Temp: 400°F

- Normal Working Tension: 12-18 pli

- Lower Permeability is achieved with monofilament stuffers

- No seam is required, the fabric ends are joined together at the time of installation

To view or download, click PDF image above

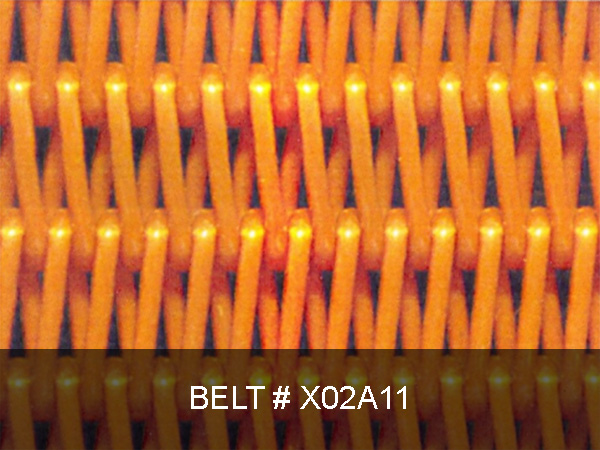

100% Monofilament Spiral Fabric with Improved Hydrolysis Resistance

Products Strengths

- Co-extruded Poly/Teflon Spiral Fabrics

- Improved contamination resistance

- Superior abrasion resistance

- Smooth surface and high contact

- Clean running

- Maximum dimensional stability and strength

- Retains permeability throughout life

Specifications

- Poly/Teflon 105PT

- CFM: 900

- MD (machine direction) yarn dia. .8 to .105 mm

- CD (cross direction) yarn dia. .9 to .105 mm

- Estimated overall thickness (measured) 3.8 mm

- Max Speed: 4000’/min.

- Min. Pulley: 4” Dia.

- Max Operating Temp: 550°F

- Normal Working Tension: 12-18 pli

- Permeability is achieved with monofilament stuffers

- No seam is required, the fabric ends are joined together at the time of installation

To view or download, click PDF image above

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.