Conveyor Belting – Who Sets The Standards?

According to Process Industry Informer:

Who sets conevoyer belt standards?

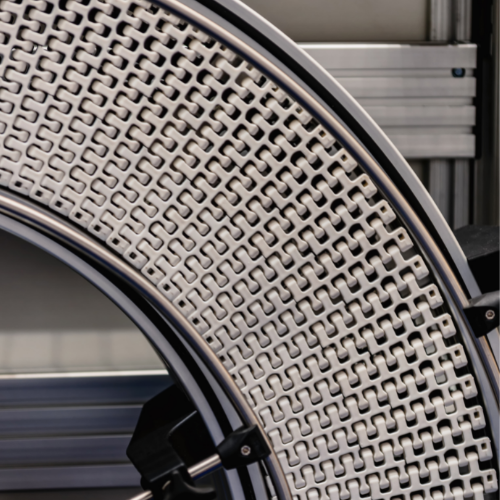

In the world of processing, conveyors continue to be an indispensable method for moving all manner of materials and products from A to B. The conveyor belt industry itself is a huge, highly competitive, cut throat market.

Although there is an abundance of manufacturers and traders, such competition does not necessarily benefit the end-user. As in any market, the relentless pursuit of orders can and does lead to compromises in safety, quality of performance and operational lifetime.

From the buyer’s perspective, mistakes when purchasing conveyor belts frequently prove to be enormously expensive in more ways than one.

Although they might seem to the uninitiated as simply super-sized rubber bands, conveyor belts are surprisingly complex and highly technical pieces of equipment.

There is an enormous variety of destructive materials and demanding operating conditions that conveyor belts have to cope with plus, of course, environmental and safety considerations.

As a consequence, there are many different belt types of conveyor belt construction and an even wider range of rubber compounds designed to protect those constructions.

This includes everything from straight-forward wear & tear, rip and impact damage to exposure to heat, oil, chemicals, ozone & UV, extreme cold and fire. With this multitude of requirements comes a bewildering range of test methods and quality standards.

European and International standards

Globally there are a number of different quality organisations who set standards for conveyor belting but the most widely accepted standards (for all types of conveyor belt) are those used in Europe. These are EN standards (European Norms), which are maintained by CEN (Committee European de Normalization) and ISO standards (International Organization for Standardization).

Both CEN and ISO are independent, non-governmental organizations and are the world’s largest developers of voluntary international standards. ISO membership consists of the quality standards organizations representing 168 countries. The prefix EN ISO refers to ISO standards that have been adopted in full as a European standard.

In many parts of Europe some specific and longer established DIN standards continue to be more commonly recognised and accepted. This is especially so in the case of abrasion resistant belting. The letters ‘DIN’ stand for ‘Deutsches Institut für Normung’, which means ‘German Institute of Standardization’.

They develop norms and standards as a service to German industry and are a highly respected non-profit organization that has been based in Berlin since 1917. A great many DIN standards have been converted into EN or even ISO standards.

Standards for conveyor belts vary between different countries. However, members of CEN are obliged to implement EN (European standards) as their national standards without modifications and withdraw any of their own national standards that may conflict with them.

It is worth bearing in mind that the standards applied to manufacturers in countries that are not members of CEN are frequently found to be significantly inferior or outdated.

Test methods and test standards are not the same

When assessing quality credentials it is essential to differentiate between what is simply an approved method of conducting a particular test (test method standard) and the actual quality or performance standard attained during that test.

The fact that a belt has been tested according to a certain method actually means very little. The most important thing to look at is the actual level of performance achieved during the testing compared against the minimum acceptable level of performance dictated by the test standard.

In other words, what was the actual performance?

Did it even achieve the minimum requirement?

For example, in the case of the ENISO 4649 abrasion resistance testing method, the performance would typically be measured against the performance standards set within ISO 14890.

When choosing which belt to buy it is essential that the technical datasheets provided by manufacturers and traders are used in the decision making process.

However, the fact is that manufacturer’s technical datasheets almost invariably only show the minimum standard demanded by a particular test.

Unless stated otherwise, the data shown does not reflect the actual performance achieved during the test and therefore in no way indicates the level of performance that the buyer can expect. And if they only show the test method reference number then they are pretty much worthless; a fact that applies to the technical datasheets provided by the vast majority of suppliers.

CE Marking

Compliance with CE quality standards is increasingly being stipulated by purchasers of industrial conveyor belts even though CE accreditation does not actually apply to conveyor belts. This is because they are not a product category subject to specific directives that are required to be CE marked. Nevertheless, it is still worth having a basic understanding of the role of CE quality standards and how they can be used to mislead.

The letters “CE” used in the CE Marking are the abbreviation of French phrase “Conformité Européene”. This literally means “European Conformity”. The term initially used was “EC Mark” but was replaced by “CE Marking” in the Directive 93/68/EEC in 1993.

When a manufacturer places a CE marking on a product they are declaring, on their sole responsibility, conformity with all of the legal requirements to achieve CE marking. The manufacturer is thus ensuring validity for that product to be sold throughout the EEA even though the mark does not mean that the product was actually made in the EEA.

This, of course, is dangerous. Some conveyor belt manufacturers, especially those in the Far East, deliberately use the CE mark to create an illusion of quality and safety based on the likely assumption that goods with CE marking is proof that the product meets strict EU standards even though no such standards exist.

Rather shockingly in my view, a very similar CE mark can frequently be seen that most consumers understandably but mistakenly believe is a genuine CE mark of European conformity. In this case it actually means “China Export”, meaning that the product was manufactured in China.

Dimensions and tolerances

In terms of dimensional standards and acceptable tolerances such as length, width, thickness etc, all textile fabric ply construction conveyor belts are subject to ISO 14890:2013. These specify the dimension requirements for rubber (and plastic) covered conveyor belting for general surface use on flat or troughed idlers.

Different tests for different demands

As mentioned earlier, there are many different types of belt and an even wider array of different types of rubber covers, which are most commonly referred to as either cover grades or cover qualities. The outer covers protect the belt carcass from whatever they are carrying. The primary rubber cover grades used in processing industries are:

Abrasion (wear) resistant

Rip & tear resistant

Oil resistant

Fire resistant

Ozone & UV resistant

There are often a combination of factors, such as resistance to fire and oil. However, one that is common to all is the ability to resist abrasive wear.

Abrasion – standards

The ability of a conveyor belt to resist abrasive surface wear is usually the single most important factor that will determine its operational lifetime and consequently its cost-effectiveness.

There are two internationally recognised sets of standards for abrasion, EN ISO 14890 (H, D and L) and DIN 22102 (Y, W and X). As mentioned earlier, in Europe it is the longer-established DIN standards that are most commonly used. Generally speaking, DIN Y (ISO 14890 L) relates to ‘normal’ service conditions and DIN W (ISO 14890 D) for particularly high levels of abrasive wear.

However, DIN X (ISO 14890 H) is regarded as the most versatile because in addition to resisting abrasive wear it also has good resistance to cutting, impact (from high drop heights) and gouging, usually caused by heavy and/or sharp materials such as ceramics.

Abrasion – testing

The test method for abrasion (ISO 4649 / DIN 53516) is actually quite simple. Resistance to abrasive wear is measured by moving a test piece of rubber across the surface of an abrasive sheet mounted on a revolving drum. It is expressed as volume loss in cubic millimeters. For example, in the case of DIN Y (ISO 14890 L) it is 150 mm³.

The key thing to remember when looking at abrasion test results is that higher figures represent a greater loss of surface rubber. This means that there is a lower resistance to abrasion. Conversely, the lower the figure then the better the wear resistance will be.

Rip and tear resistance – testing

Rip & tear resistance is not a cover grade in its own right. However, the ability to withstand the forces that rip and tear belts can often be more important than any other physical attribute. Even the strongest, heaviest belts can be punctured and ripped by a foreign object becoming trapped.

A ‘tear’ is best described as what happens when a section of belt is pulled apart in opposing directions. In contrast, a ‘rip’ is what happens when a sharp object punctures the belt and cuts the belt longitudinally as it is pulled against the trapped object.

There are currently no internationally accepted test methods or standards for testing rip resistance. Manufacturers in the USA such as Fenner use a round pin that is pulled through the belt whereas Dunlop in the Netherlands pull sections of belt through a right-angled piece of metal, which they have fondly nicknamed ‘Jack the Ripper’.

Fortunately, there is an international standard for tear strength. The ISO 505:2017 test method measures the propagation resistance of an initial tear in textile conveyor belts, either in full thickness or of the carcass only. This test is intended for application to textile belts in installations where there is a risk of longitudinal tearing.

Although the method of testing is defined there are, as yet, no standardised performance requirements. The test basically consists of mounting two cut ends of a test piece of belting in the jaws of a tensile testing machine.

An initial tear is made in a test piece, which is then pulled apart in opposing directions. The force necessary to propagate the tear is then measured. Examination and analysis of the multi-peak tear resistance test traces are made in accordance with ISO 6133.

Perhaps not surprisingly, most manufacturers, primarily those manufacturing what are euphemistically referred to as ‘economy belts’ make little or no mention of rip and tear resistance. Unless specifically designed to resist ripping and tearing, even the thickest, heaviest belts will rip like paper because the type of fabric ply used in the carcass simply is not designed to cope with such forces.

Oil resistance

Many bulk materials, especially grain and biomass, contain oils and resins. When oil of any kind penetrates rubber it causes it to swell and distort. This results in serious tracking and steering problems, premature wear and ultimately premature replacement.

Oils are divided into two distinct sources – mineral and vegetable/animal. The two best recognised test methods for oil resistance (both of which involve almost identical test procedures) are ISO 1817 and the comparable, slightly less elaborate but equally tough American ASTM ‘D’ 1460.

Even some of the biggest manufacturers of belting in the world use the DIN reference number 22102 G when referring to oil resistant belting. This is very misleading because the letter ‘G’ simply denotes oil (or grease).

However, the truth of the matter is that DIN 22101 G does not actually contain any requirements, test methods or limits that are specific to oil resistant belting. This is yet another classic example of how simply displaying a test method reference number is designed to provide reassurance to the buyer but in reality is meaningless in terms of actual performance.

Oil resistance test methods

The ISO 1817 and ASTM ‘D’ 1460 test methods are both used to measure the effect of oil (and other liquids and chemicals) on vulcanised rubber. Samples of rubber (eg. 100mm X 1.6mm X 2mm strips for the ASTM test) are fully immersed in the relevant test liquid for a specific period of time.

The duration of immersion and the temperature at which the liquid and sample are kept can be varied but the most common is either 3 or 7 days at ambient or 70°C.

The ambient temperature of the environment is controlled within specific guidelines. Changes in the geometry and dimensions of the specimen caused by absorption are then measured when the samples are removed.

Although there are no actual performance standards in existence, it is still important to look for actual references to the test methods used by the manufacturer/supplier. I find it quite disturbing to note that only one manufacturer (Dunlop again I have to say) makes any mention whatsoever concerning the actual test methods used to determine the oil resistance qualities of their belts.

Fire resistant belting

Although fire safety is an enormously important issue, it is quite amazing that such little care and attention is paid during the selection and buying process. Sadly, it often seems that having paper accreditation and certification to avoid culpability is sufficient reason to buy.

There are numerous safety classifications, international standards and many different tests used to measure the self-extinguishing properties of conveyor belts.

Test methods and performance standards vary enormously depending on whether a belt is for use above or below ground. For the processing industry I have focused purely on the requirements for belts being used above ground.

Basic conveyor belt testing

The basic test for belting used in normal ‘above ground’ industrial applications is EN/ISO 340. This standard makes the distinction between fire resistance with covers and fire resistance with and without covers.

The relevance of “with and without covers” is that over time, wear reduces the amount of fire resistant rubber protecting the inner carcass, which most commonly consists of flammable polyester/nylon fabric plies.

Although no longer used in the current EN ISO 340, the market still commonly refers to grades ‘K’ for testing with covers attached and ‘S’ for testing both with and without covers. This originates from DIN 22103 which was used as the basis during the creation of EN ISO 340.

EN/ISO 340 tests involve exposing 6 individual samples of belt to a naked flame causing them to burn. The source of the flame is then removed. A current of air is then applied to the test piece for a specified time after the removal of the source of fire.

The time it takes for the belt sample to self-extinguish after the flame has been removed is then measured. The duration of continued burning (visible flame) should be less than 15 seconds for each sample with a maximum cumulative duration of 45 seconds for each group of six test samples. This determines how fire can be carried along a moving belt.

The buyer should still exercise caution even if a manufacturer states that their belt has passed the ISO 340 test. A burning conveyor belt can spread fire a considerable distance in 15 seconds. The real measure of a good quality, safe fire resistant belt is the time it typically takes to self-extinguish. This could and should be as quick as one second. If you are at all unsure of what level of fire resistance you need then it is best to seek expert advice.

Ozone & Ultra violet resistance

Although not commonly known (or even mentioned by most manufacturers) an absolutely essential quality that all rubber belting should have is the ability to resist the damaging effects of ozone and UV.

Although not an actual cover grade in its own right, there is no question that all rubber belts need to be fully resistant to ozone and UV light. This is because at ground level, ozone becomes a pollutant that attacks rubber by increasing the acidity of its carbon black surfaces and causes reactions to take place within the molecular structure of the rubber.

This has several consequences including significant surface cracking and a marked decrease in the tensile strength. Likewise, UV light from sunlight and fluorescent lighting also accelerates deterioration. This is because ultraviolet produces photochemical reactions that promote the oxidation of the surface of the rubber, resulting in a marked loss of mechanical strength. Ozone and UV combined really are invisible belt killers.

EN/ISO 1431 international standards

To scientifically measure resistance to ozone, samples are placed under tension (eg. 20% elongation) inside the ozone testing cabinet and exposed to highly concentrated levels of ozone for a period of time (eg.up to 96 hours).

Samples are closely examined for evidence of cracking at two-hourly intervals and the results carefully measured and recorded. Experience has shown that for the rubber to be adequately resistant the pass criteria needs to be that there are no signs of cracking after 96 hours (@ 40°C, 50 pphm and 20% strain) inside the ozone cabinet.

As I mentioned earlier, despite its crucial importance, ozone and UV resistance is very rarely, if ever, mentioned. This is almost certainly because costly anti-ozonants need to be used during the mixing process of the rubber compounds.

A recent series of samples of rubber belt originating from Asia revealed that every single sample had virtually nil resistance to ozone and ultraviolet. My advice is to make ozone & UV resistance a constant requirement when selecting any rubber conveyor belt.

Conclusions

Quality standards and testing in the conveyor belt industry is a huge and often complex subject. What I have endeavoured to do is simply provide a basic guide. Never assume that seeing the presence of test method reference numbers or the logos of quality organisations necessarily means what they are designed to indicate.

It is always worth taking the time and trouble to ask questions and request evidence of best practice and, above all else, actual performance. Raw materials alone make up some 70% of the cost of manufacturing so in the case of conveyor belts, highly attractive pricing should start the alarm bells ringing. Taking that little bit of extra care could easily save your company an enormous amount of time and money.